Parent Company : Dezhou Ruixing Water Purification Materials Co., Ltd.

Address:NO.1706, Shengyuan Road, Tianqu Industrial Park, Dezhou,Shandong,China

General Manager:Chang Yinghua

Phone Number:

0086-534-2310678

Mobile Number:

0086-13853486309

Mobile Number:

0086-13791355791

Company Mailbox:

ruixingwater@ruixingjs.com.cn

Mailbox:ruixingjs@163.com

Website:www.ruixingjs.com.cn

Website:www.dzruixing.cn

Website:www.sdruixingjs.com

Fax:0086-534-2217208

Postal Code:253000

Waterworks Sludge and Tank Sludge Water Treatment Technology02

时间:2021-04-07浏览次数:528次

4. Sedimentation tank sludge water and filter flushing wastewater treatment or handling problems were merged

Sedimentation tank in Waterworks (or clarifier) fixed rate higher than 0.3% suspended impurities mud water, solid rate high, more than thirty times than the filter containing rinsing wastewater sedimentation tank; such as the implementation of intelligent and reasonable mud, sludge solid content is probably around 1%. Daily water plant filter washing waste water, and generally significantly more than the sedimentation tank sludge water content. Therefore, if the precipitation combined treatment pond sludge and filter flushing wastewater together into the same regulation pool, although the ratio process obviates the wastewater regulation tank, reduce the capital investment and land, but the sedimentation tank sludge was filter washing wastewater extreme dilution, sludge thickening effect is not conducive to concentrated pool later, concentrated pool due to deal with large amount of water, concentration effect is poor and need to increase investment in infrastructure and land. Therefore, water treatment plant sludge generally adopt process two kinds of sludge were treated, water quality, water wastewater regulation tank in the concentration homogenized after filter washing wastewater, the general can pump to flocculation pool for water use; also can be wastewater regulation tank bottom sediment concentration in the sediment liquid pump enter the thickener concentration, the remaining amount of wastewater pump to flocculation precipitation pool as raw water.

5. Thickener sludge water pool type and design structure points to note

Gravity continuous flow of concentrated sludge water pool has a variety of different cell types and structural form, the total can be summed up as a general thickener sludge water and has a swash plate thickener sludge water II. Many of our water plant is currently facing in response to micro-polluted raw water depth to provide water biological pretreatment and sludge treatment processes and new infrastructure such as water treatment systems transformation task, shortage of land is the reality of the existence of many water problems. Thickener sludge treatment system footprint is larger structures, with a swash plate thickener sludge water can effectively improve the process of concentration of solids flux, thereby significantly reducing the concentrated pool area.

Because the water plant sludge and sewage sludge in the organic composition ratio, sludge content, the proportion of the sludge and properties are fundamentally different, so these two kinds of sludge concentration tank should be totally different in the solid flux and solids in a concentrated tank design parameters such as the mean residence time. For different source water of water plant, due to the suspended impurities in raw water particles content and distribution of different algae in water, solid particles also affect the water plant sludge water settling velocity and solid liquid separation performance, so in the design to determine the different water sludge water thickening pool area, in general should be sedimentation tank suitable sludge static settlement test, even dynamic settlement test, to obtain a more exact concentration tank design parameters such as solid flux.

Waterworks Sludge settling particles in the concentrated pool was crowded with some flocculation settlement process, the concentrated sludge water from the pool into a certain depth below the surface of the pool was concentrated. Swash plate thickener solid-liquid separation can not be used to stream under way on the use of lateral flow and flow combination of solid-liquid separation process concentrated sludge water.

In order to effectively promote uniform flocculation tank sludge particles concentrated among large knot, the lower concentration tank should be set straight with gentle stirring rod bottom sludge scraper device assembled mixing device.

6. Sludge flood storage pool balance settings problem

Waterworks sludge thickener sludge discharged concentrated solid content of about 3% to 4% of the general input directly to the mechanical dewatering of sludge dewatering room.1998 put into operation in Shanghai Minhang a water treatment plant sludge treatment system for the first time between the sludge thickener and centrifuge sludge dewatering room set up a homogenized concentrated sludge regulate the quantity and quality of sludge flood storage role balancing pool.

Sludge dewatering machine from mechanical operation efficiency higher and higher solid content of the mud (mud cake water treatment plant sludge dehydration after solid containing rate generally require more than 35%, to meet the needs of Sinotrans disposal of sludge), fixed rate basically stable containing concentrated sludge dewatering machine requirements into. At the same time adjustment from the running process of the sludge dewatering machine (such as the plate and frame filter press remove mud cake and cloth washing) and mechanical repair, concentrated sludge supply can also request basically stable. Set the appropriate storage tank volume of sludge equalization tank to meet these demands, especially for water supply larger or the use of plate and frame filter press sludge dewatering machine periodic intermittent operation of the waterworks.

7. Selection mechanical sludge dewatering problems

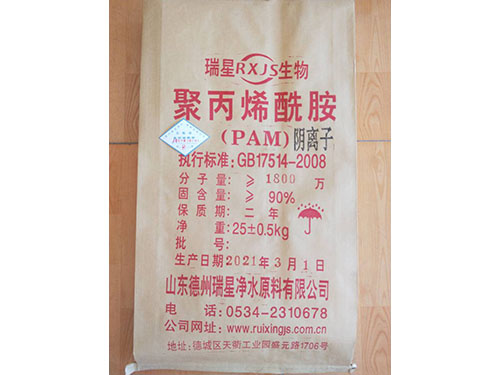

Sludge dewatering machine water plant, mainly by the belt type filter press, membrane type filter press and three types of centrifugal dewatering machine. Waterworks sludge concentration by adding appropriate amount of PAM chemical amendments by the mud cake dewatering dehydrated from outside the factory for landfill, landfill cover material or resource utilization and disposal.